In today’s competitive e-commerce environment, order fulfillment speed and accuracy are critical. The Wipe On Printer Applicator streamlines operations, especially for labeling hot-selling SKUs. It combines ServoPrint technology with fast labeling to support batch processing and supply chain transparency. Its rugged design and integration with packaging machinery make it a preferred solution for e-commerce fulfillment and express delivery centers.

Accelerating E-Commerce Throughput

The Wipe On automatic label applicator can handle thousands units per hour at customer demand rates, and can quickly label the express shipping labels of the hot-selling SKUs in batches. The system uses a unified shipping label size that meets the requirements of standard shipping, ensuring that barcodes and shipping information are legible. The applicator’s high-speed thermal direct printing provides sharp, smudge-free labels on demand, eliminating the need for pre-printed inventory and reducing waste.

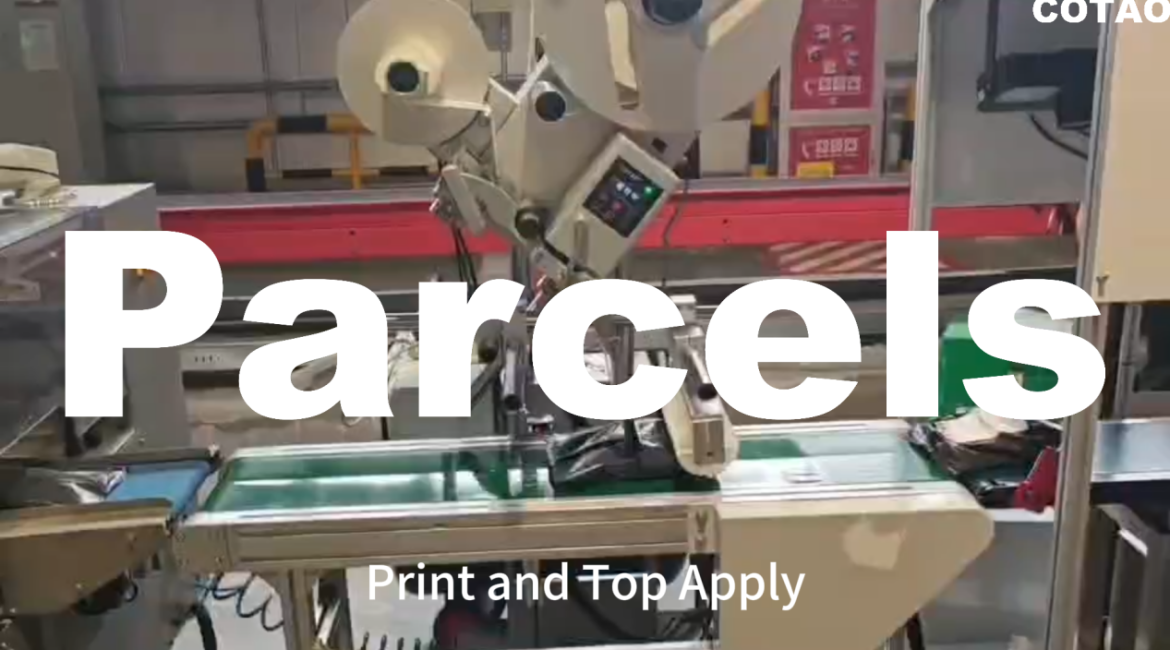

Seamless Integration with pillow packaging machine

The Wipe On print and apply labeler can be used in integration with pillow packaging machine . After the machine seals the bags, the 10L prints and applies the label to the top surface of the package not more than 800 milliseconds, making it ideal for clothes, stationery and so on. The smooth wipe-on action ensures even application, even on slightly textured surfaces.

Automated Vision and Quality Assurance

Accuracy is further enhanced with an vision inspection system that reads barcodes and shipping ID after labeling. An integrated reject mechanism diverts the device if a label is unreadable or misaligned, ensuring only properly labeled bags continue to be labeled. This closed-loop design ensures the integrity of popular items, reducing the likelihood that deliveries will not reach customers on time.

Fast Batch Labeling

E-commerce fulfillment centers often ship hot-selling SKUs in one wave batches. The Wipe On print and apply labeling system supports dynamic label content, automatically updating batch shipping identification labeling without manual intervention. Fulfillment operators simply load the product batch and initiate the packaging, printing and labeling process. Labels clearly display the order number, express barcode and shipping information – this is crucial for logistics traceability.

Case Study: Hot-Selling plush toys SKU Batch Fulfillment

A large toy e-commerce company deployed a Wipe On print and apply machine to manage orders for its best-selling plush toys. Running up to 4,000 units/hour, the system seamlessly integrates with its pillow packaging machine, printing 76×130 mm labels with order numbers and shipping information. A vision system inspects each label and a reject mechanism filters out any defective labels. As a result, the company achieved a 10% increase in throughput, zero labeling errors, and full compliance with e-commerce order fulfillment center’s standards—all while reducing labor costs by 80%.

Conclusion

The Wipe On print and apply system provides a powerful and scalable solution for e-commerce order fulfillment. It seamlessly integrates with a pillow packaging machine, on-demand thermal direct printing, and vision inspection to ensure fast, flexible, and error-free batch shipping identification labeling for hot-selling items. With throughput of up to 4,000 units per hour, it is an ideal tool for retailers looking to increase speed, accuracy, and customer satisfaction in a competitive market.

Keywords:

Wipe On Printer Applicator, Wipe On automatic label applicator, thermal direct printing, Wipe On print and apply labeler, Wipe On print and apply labeling system, Wipe On print and apply machine, Wipe On print and apply system