Introduction

In the evolving food packaging industry, food packaging has become an important method for preserving freshness and extending shelf life. However, effective labeling on flexible packages and films remains a challenge due to differences in package size, label placement and production capacity. COTAO CONUS 1102 Top-Bottom Packaging Printer offers a flexible, reliable and fully customizable solution that can be tailored to the specific needs of food manufacturers using flexible packaging. Whether top labeling, bottom labeling, with or without printing, the CONUS 1102 easily adapts to the needs of modern production lines up to 45 ppm (package per minute).

Built for Diverse Labeling Scenarios

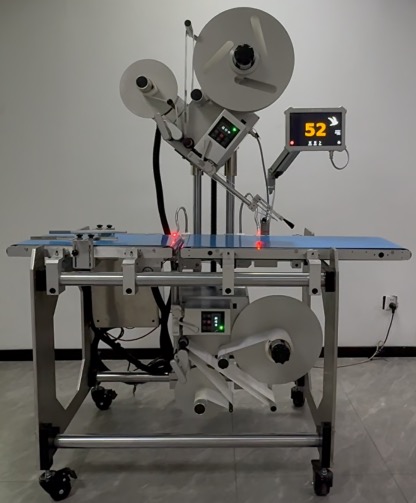

The CONUS 1102 is an integrated servo-controlled wipe-on printer applicator that is compatible with both printed and overprinted label applications. It is suitable for handling top or bottom labeling of various tray, bag, flexible package or film sizes and is commonly used for packaging baked goods, meats, seafood, prepared foods, beverages, dairy products or other foods. Its manually adjustable height handle enables the operator to readjust the labeling height in seconds, ensuring accurate label positioning regardless of product thickness or line variations.

Flexibility is the Core Advantage

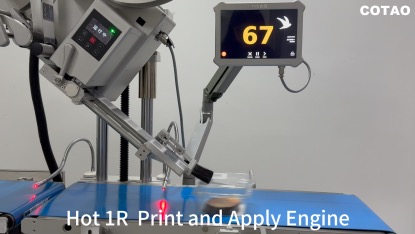

The system can operate in full print-and-apply mode or apply labels, depending on user needs. The CONUS 1102 features servo-printing technology, allowing traceability, compliance, and visual branding to coexist seamlessly.

Improved Workflow with Full Line Integration

By combining the CONUS conveyor platform with the wipe-on print-and-apply system, the system provides enhanced control over label placement and conveyor timing. Label application is smoother, even during high-speed production runs. The system also reduces downtime with fast label roll changes and an easy-to-clean stainless steel frame, making it ideal for food-grade environments.

Case Study: MAP Salmon Tray Packaging

A seafood processor needed to label both the top and bottom of MAP-sealed trays of salmon. The challenge was twofold: apply a traceability barcode to the bottom of the tray and a marketing label to the top of the tray without interrupting the high-speed line. The CONUS 1102 features a dual-station setup—two synchronized systems that accurately apply labels to each tray as it passes. The height-adjustable handle enables operators to quickly recalibrate for varying tray depths, increasing uptime and ensuring label alignment. The end result: reduced labor, increased throughput, and compliance with its barcoding requirements.

Conclusion

As food packaging standards continue to improve and the demand for customized production lines continues to grow, the CONUS 1102 Top-Bottom Food Packaging Printer can meet the precision, adaptability and efficiency required for most food packaging. Its double-sided labeling capabilities (top and bottom), combined with a height-adjustable handle and seamless integration with upstream or downstream equipment, make it the first choice for food processing, packaging and distribution suppliers who require traceability, flexibility and consistency. Whether printing、overprinting or pre-printed labels, the CONUS 1102 is the ideal food packaging printer for a variety of food packaging scenarios. Cotao can provide high-speed print engines with agile R&D and faster delivery, helping you to start quickly, operate efficiently, and gain early advantages in a competitive market.

Keywords: food packaging printer, CONUS 1102 Top-Bottom Packaging Printer, Top labeling, Bottom labeling, Wipe-on printer applica,45 PPM