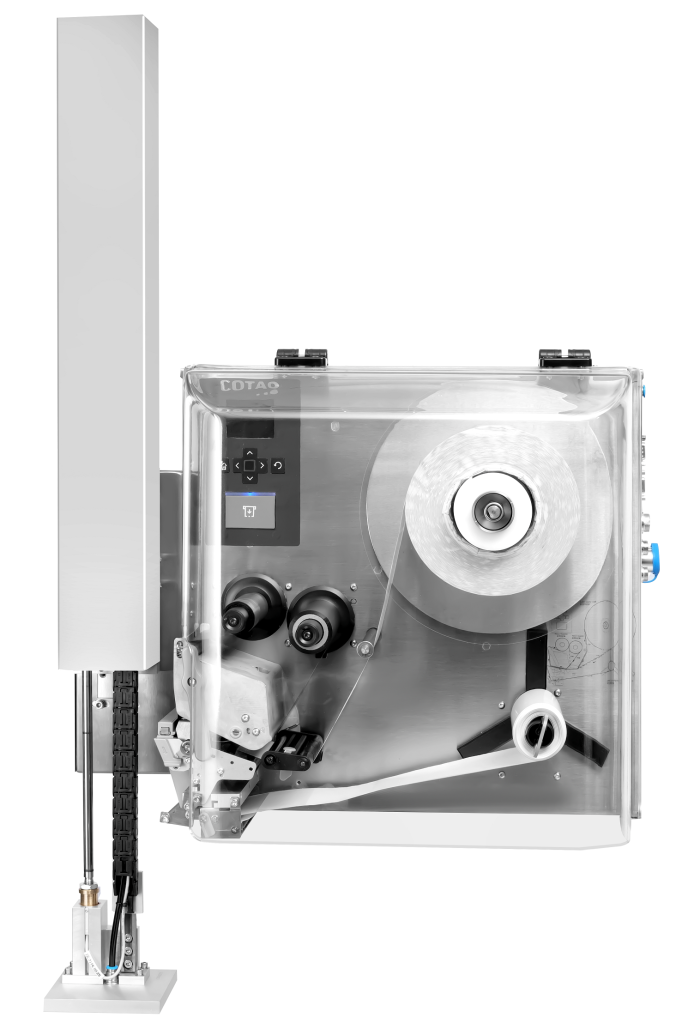

Paired with the Mid-H4 label feeder, the H400A High printer applicator is capable of printing labels up to 105.7mm wide and at 300 dpi resolution using thermal transfer technology. This ensures that each label is clear and durable.

The Par-1 Pneumatic Tamp labeling actuator, with a 300mm stroke length and 200mm effective application length, provides smooth, precise label placement on the side of the products or the boxes. The included HD-10 Tamp-Blow labeling plate accommodates labels up to 100mm x 100mm in size, ensuring versatility for a wide range of labeling needs.

One of the standout features of the H400A is its ability to integrate with AGV (automated guided vehicle) loading methods for automated material loading. The AGV delivers the products or boxes to the printer applicator, eliminating the need for manual handling. This automated approach not only improves operational efficiency, but also enhances workplace safety by minimizing human contact with heavy or bulky materials.

The H400A takes automation one step further with wireless data transfer and wireless control signals. Wireless connectivity facilitates faster data exchange, enabling the H400A to instantly receive label information, product details, and control commands. This feature is particularly beneficial in dynamic production environments where labeling requirements may change frequently.

With a print and apply cycle of just 4 seconds per label, the H400A high-print labeler is ideal for high-throughput operations. Label tolerance of ±1 mm ensures that every label is accurately applied even in fast-paced production lines. By automating the labeling process and combining it with AGV loading and wireless communication, the H400A helps manufacturers minimize errors.

Video:

Keyword:

H400A High Printer Applicator, AGV feeding, wireless data transmission, wireless control signal transmission, automatic print and apply